Integration and evaluation of a natural gas-ammonia complementary powergeneration system based on ammonia-driven calciumlooping for CO2 capture

2024 No. 12

2024 No. 12

611

611 249

249

Citation format:

Authors:

- ZHENG Yawen

- ZENG Xuelan

- LIU Jianhui

- WANG Junyao

- HE Song

- YANG Guang

- FAN Junming

Unit:

- Collaborative Innovation Institute of Carbon Neutrality and Green Development,Guangdong University of Technology

- Shenzhen Gas Co.,Ltd.

- School of Material and Energy,Guangdong University ofTechnology

Abstract:

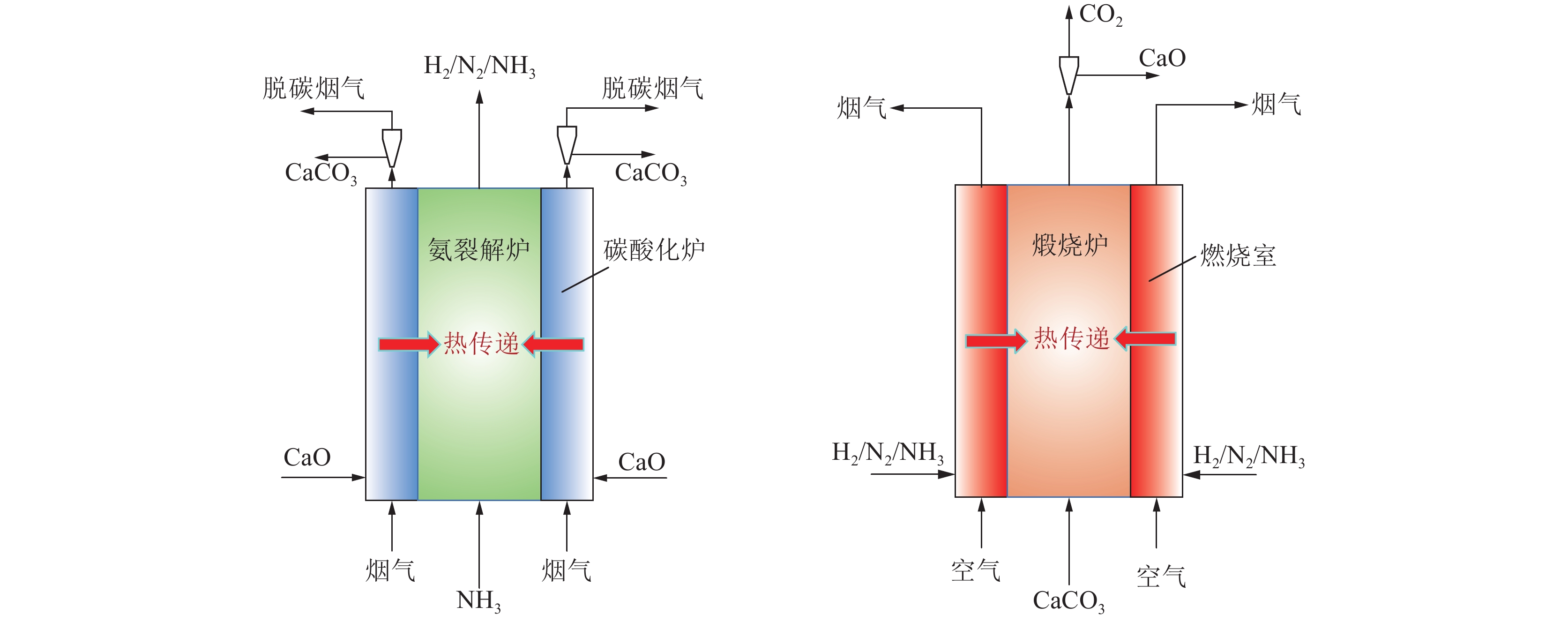

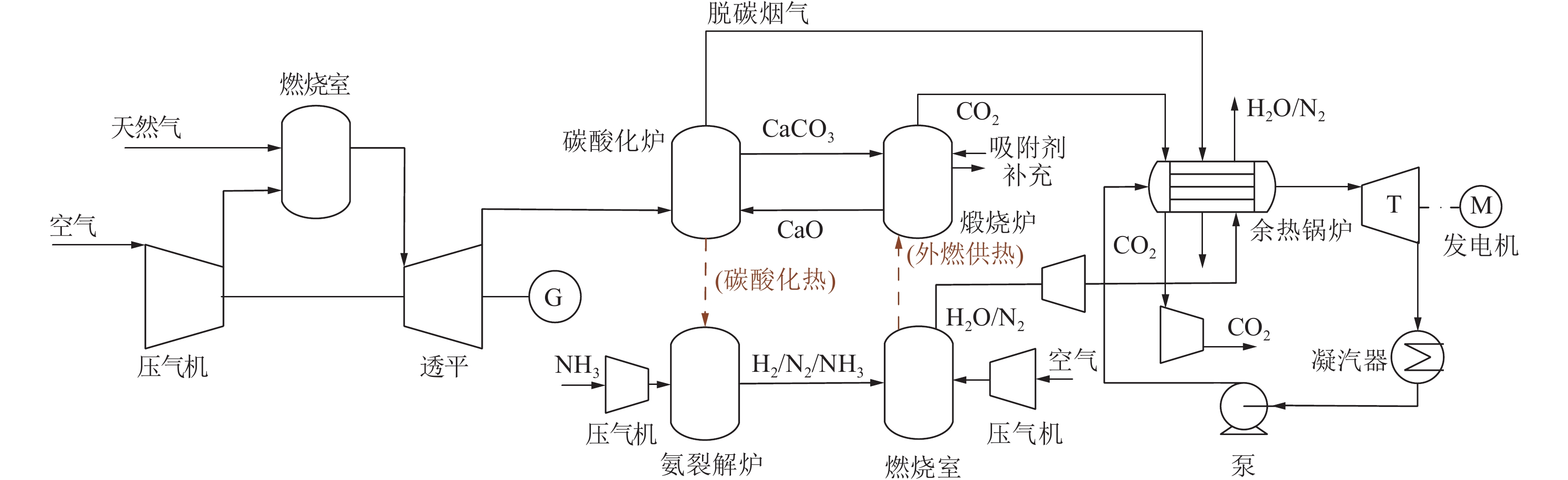

Natural gas power plants will play an important role in scenarios with high renewable energy input due to their clean,efficientand excellent peak-shaving capacity. Although natural gas power plants have lower carbon emission intensity compared to coal-firedpower plants,they remain a major source of global CO2 emissions. CO2 capture,utilization,and storage (CCUS) technologies areessential for achieving carbon neutrality, with post-combustion calcium looping technology drawing significant attention due to thewidespread availability and low cost of its absorbents. Traditional oxy-fuel calcium looping capture technology uses pure oxygen and fossilfuels to supply heat for the calcination process and recovers the constant-temperature heat from the carbonation reaction by directlyheating steam,resulting in high energy penalties. A novel ammonia-driven calcium looping CO2 capture system for natural gas-ammoniacomplementary power generation has been proposed,in which ammonia replaces fossil fuels as a zero-carbon fuel. This new system avoids the additional carbon capture demand caused by fossil energy heating and utilizes ammonia pyrolysis to recover medium-temperature heatreleased from the carbonation reaction, avoiding large temperature difference heat exchange losses when directly heating steam. Theresults show that,compared to traditional oxy-fuel calcium looping systems,the efficiency penalty of the new system drops from 9.4% to0.6%, and the CO2 avoided energy consumption decreases from 4.7 to −8.1 MJ/kg, significantly improving its thermodynamicperformance. At the same time,the carbon emission intensity of the new system is significantly reduced compared to the oxy-fuel calciumlooping system,reaching 18.6 kg/MWh. An analysis of the effect of gas turbine inlet temperature and pressure at ammonia side on the newsystem’s performance shows that the new system performs well across a wide range of operating parameters.

Keywords:

- ammonia

- calcium looping

- post-combustion capture

- natural gas combined cycle power plant

- system integration

Citation format:

Chart:

Articles:

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors