Hydrogen production from steam reforming of long chain hydrocarbon fuelsusing pyrochlore supported catalysts

2025 No. 02

2025 No. 02

546

546 191

191

Citation format:

Authors:

- LI Lin

- WANG Yurui

- LI Shuang

- SHI Yixiang

Unit:

- Shanxi Research Institute for Clean Energy,Tsinghua University

- Department of Energy and Power Engineering,KeyLaboratory for Thermal Science and Power Engineering of Ministry of Education,Tsinghua University

Abstract:

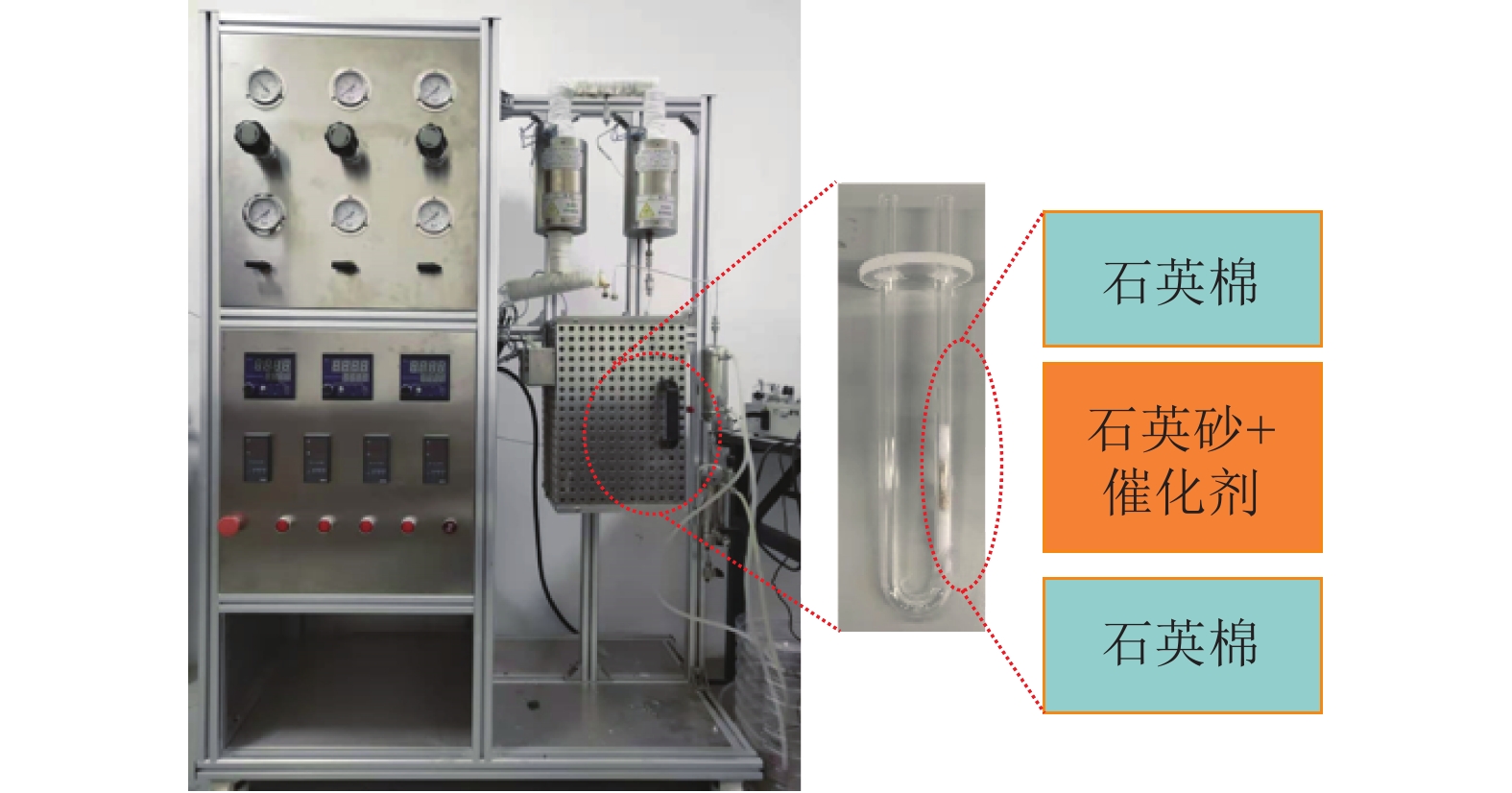

Hydrogen-rich syngas production via diesel steam reforming (DSR) is of great interest because of the high H2/CO ratio andthe availability of external heat sources. However,due tothe elongated carbon chains and intricate composition in diesel fuels,there aresome technical challenges such as low hydrogen yield,hot sintering at high temperature and carbon deposition in the process of hydrogenproduction In order to achieve efficient reforming of diesel for hydrogen production,an innovative catalyst using pyrochlore carriers withdifferent A-site cations (La/Pr/Sm) and a B-site consisting of the Ce element as a carrier supported by precious metals Rh wassynthesized. Because the carrier has a better oxygen mobility,the performance of diesel reforming is improved,and the occurrence ofcatalyst carbon deposition is alleviated. Raman and EPR results shows,comparing Pr2Ce2O7、Sm2Ce2O7 andCeO2 carriers,La2Ce2O7carrier contains the highest amount of oxygen vacancies and superoxide ions (). Furthermore,XPS and O2-TPD results indicate,contrast with other Rh-supported catalysts,3%Rh/La2Ce2O7 catalyst formed more abundant and active surface adsorbed oxygen species,which is closely related to the best performance of 3%Rh/La2Ce2O7 catalyst in n-hexadecane steam reforming. The 3%Rh/La2Ce2O7catalyst exhibited the highest conversion rate reached up to 97.2%,the highest hydrogen volume content at 70.2% and the lowest by- product volume content. Specifically,the CH4 volume content was 0.03%,C2H4 content was not been founded due to below the detectionline 0.000 01%,and the volume content of C2−C5 hydrocarbons was merely 0.000 5%. Notably,the 1%Rh/La2Ce2O7 catalyst with furtherreduction of Rh content,when applied in the steam reforming of actual fuel diesel,the performance is only slightly worse than that of n-hexadecane reforming,the conversion rate still reached up to 97.2%,hydrogen volume content achieves 67.9%,with remarkably low by-product volume contents of 0.15% methane,0.04% ethylene,and 0.07% C2−C5 hydrocarbons. This catalyst exhibits outstanding reformingperformance and demonstrates excellent resistance to carbon deposition,thereby showing a great potential in large-scale engineeringapplication.

Keywords:

- reforming for hydrogen production

- hydrogen production via diesel reforming

- steam reforming

- pyrochlore carrier

- reforming catalyst

Citation format:

Chart:

Articles:

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors