Helium extraction process by cryogenic liquefaction of enriched coalbed methane

2023 No. 11

2023 No. 11

504

504 268

268

Citation format:

XU Jizong,LI Xuefei, YUAN Chongliang, et al. Helium extraction process by cryogenic liquefaction of enriched coalbed methane[J].Clean Coal Technology,2023,29(11):167-177.

Authors:

- XU Jizong

- LI Xuefei

- YUAN Chongliang

- WANG Yongzhong

- ZHANG Junliang

- GUO Haoqian

- LI Xiaoliang

Unit:

- Yaojie Coal and Electricity Group Co.

- China Coal Research Institute Co.,Ltd.

- Beijing Key Laboratory of Coal Based Carbon Materials

- National Energy Technology & EquipmentLaboratory of Coal Utilization and Emission Control

Abstract:

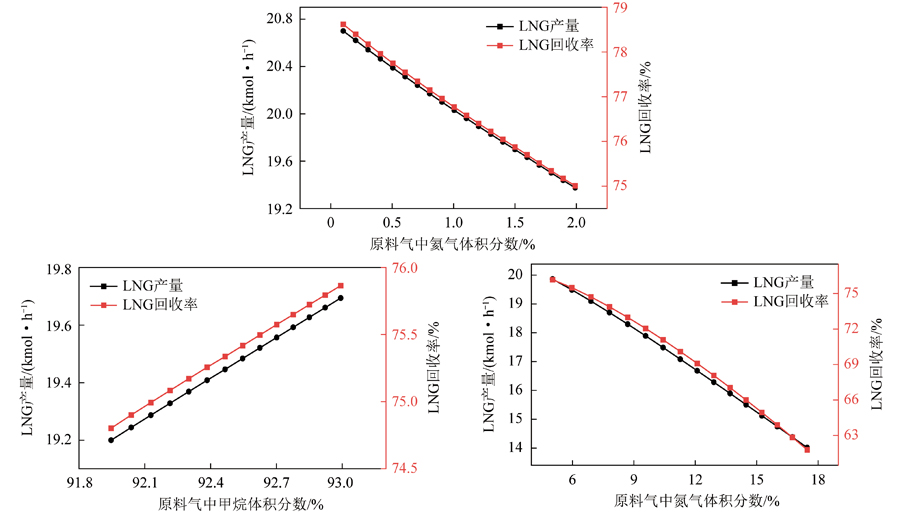

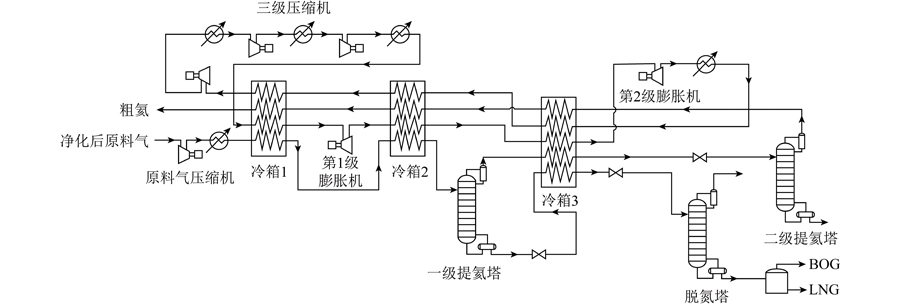

Helium is one of the important national strategic gases, and the extraction of helium from natural gas is its main industrialsource. China is severely constrained by helium monopoly countries due to the lack of natural gas. It is extremely urgent to find the new resources for helium extraction. Helium extraction from concentrated coalbed methane, which is similar to natural gas and does not require complex pretreatment, could be an important direction for China to break the helium " stuck neck" . The extraction of heliumfrom concentrated coalbed methane with the co-production of LNG was simulated by Aspen HYSYS, and the influence of intake air temperature, intake air pressure, reflux ration, theory plate number, feed position and composition of feed gas on the energy consumption ofhelium extraction by cryogenic liquefaction, crude helium and LNG quality was analyzed. The results show that the main energy consumingequipments of helium extraction from concentrated coalbed methane by cryogenic liquefaction are compressor and expander from cycle refrigeration, condenser and reboiler from helium extraction, respectively. The separation effect of helium extraction by cryogenicliquefaction is better under the conditions of low temperature and high pressure of inlet gas. The investment cost of helium extraction bythe cryogenic liquefaction is the lowest and the economy is good, when the number of theoretical plates of the primary and secondary helium extraction tower and denitrification tower are 8, 7 and 4, respectively. The concentration of crude helium is increased from 66.68% to70.49%, the recovery rate of helium is increased from 99.67% to 99.93%, and the output of crude helium is increased from 7.47 m3 / h to13.28 m3 / h by two-stage low-temperature condensation, with the CH4 concentration of the feed gas is increased from 86% to 93%, theHe concentration is increased from 0.8% to 1.5%, and the N2 concentration is reduced from 13.2% to 5.5%. For the production scale of15 000 m3 / d, the total investment of the cryogenic liquefaction helium extraction system of concentrated coalbed methane is about19.46 million RMB, of which the nitrogen cycle refrigeration compressor accounts for the largest proportion, about 65.58%. The crude helium and coproduct liquefied natural gas (LNG) can be produced from concentrated coalbed methane by cryogenic liquefaction which willbe helpful for industrial application of helium extraction from coalbed methane.

Keywords:

- helium

- coalbed methane

- cryogenic liquefaction

- helium extraction process

- Aspen HYSYS simulation

Citation format:

许继宗(1965—),男,甘肃陇西人,正高级工程师,硕士。E-mail:2767907796@qq.com

Chart:

Articles:

--

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors